GMI’s CIP3 interpreter module uses plate data to compute the needed ink key positions, so you can adjust prior to press start

Presetting

GMI’s CIP presetting option for our Mercury or Clarios system is designed to enable today’s electronic workflows. The same RIP that creates bitmap files for the plate-maker also creates a summary file of the plate images. GMI’s CIP presetting will utilize that information to calculate initial ink key positions before the press starts, achieving 85% to 90% of good color on the 1st pull.

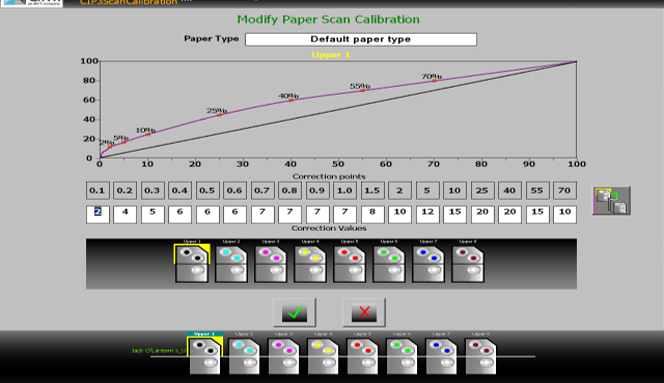

The image area coverage is computed from the same digital data that is used to create the plate, and the AutoScanCal feature utilizes continually-learned correction curves to adjust for the differences in ink formulation, paper printability, roller wear, and general press condition. Inexperienced operators are able to reach shippable product almost as fast as experts. If you don’t have a CIP3 presetting system, the return on investment from installing one is usually just a few months.